Our Services

Southside Auto Repair and Tire is your ONE STOP AUTO REPAIR SHOP! We’ve got you covered from A-Z and can help you with any automotive repair, tires, alignments you name it. We’ll get you back on the road in a timely proficient and safe manner. Stop by Southside Auto Repair in Pueblo for all your automotive needs.

(719) 561 1392

Services Detail Overview

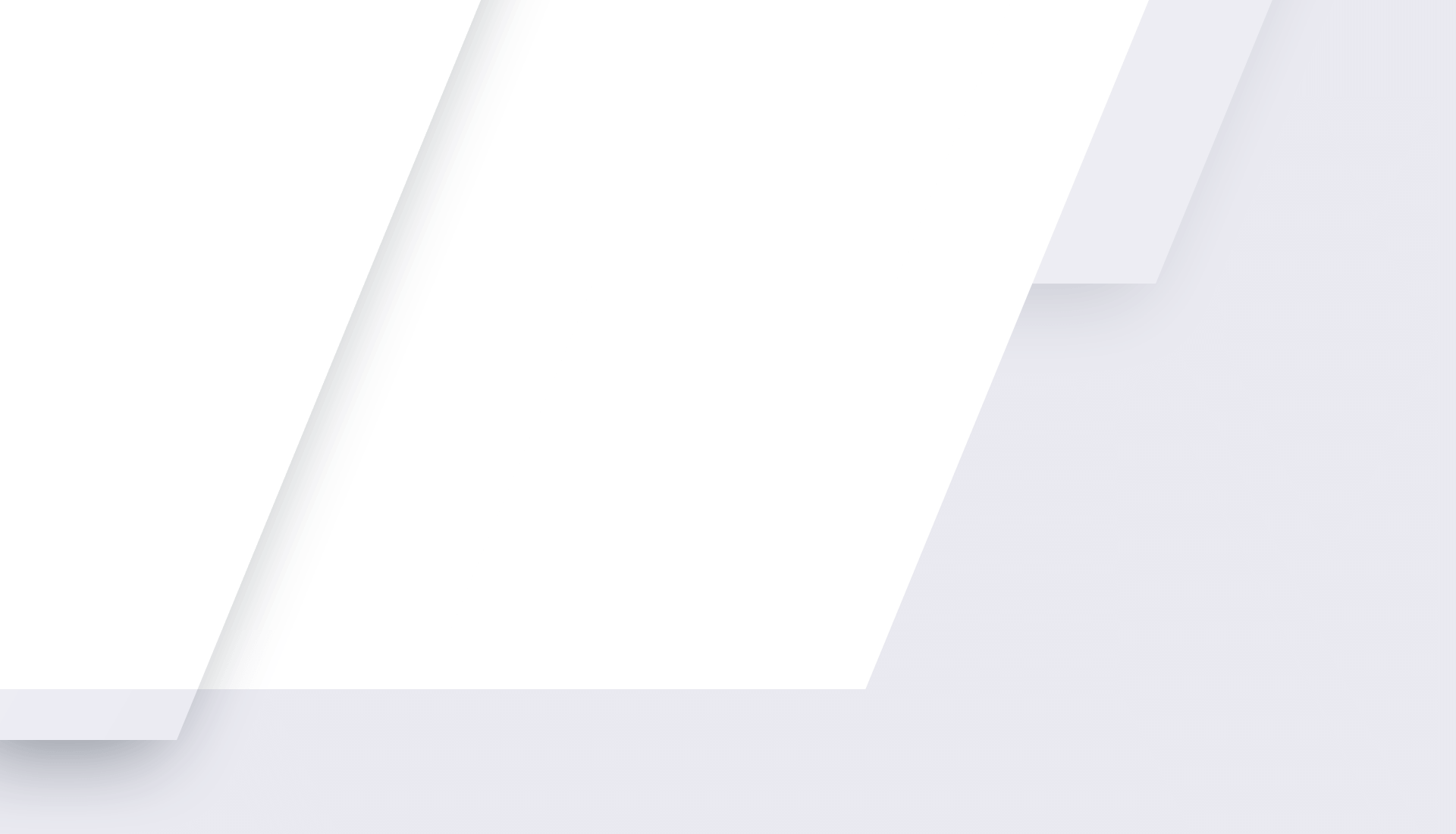

Battery, Starting and Charging Systems

We can help you choose the right battery for your vehicle and lifestyle. Our staff can safely and professionally install your battery and get you back on the road.Your car’s electrical system powers everything from the ignition and fuel systems to accessories such as your radio, headlights and wipers. The electrical system is, in turn, powered by the engine. Here are the three key components of the electrical system:

We can help you choose the right battery for your vehicle and lifestyle. Our staff can safely and professionally install your battery and get you back on the road.Your car’s electrical system powers everything from the ignition and fuel systems to accessories such as your radio, headlights and wipers. The electrical system is, in turn, powered by the engine. Here are the three key components of the electrical system:

Battery

When your car’s engine is off, the battery provides the required power to the rest of the system, as well as during start-up (cranking). It also supplements the power from the charging system during periods of high demand.

Charging System

This is the heart of the electrical system. It consists of three main components: the belt-driven alternator, various electrical circuits, and a voltage regulator. The alternator supplies power to the electrical system and recharges the battery after your car has started. Just like it sounds, the voltage regulator controls the voltage, keeping it within the operating range of the electrical system.

Starting System

This system consumes more electrical power than any other in your car. The starting system consists of three components which work in tandem: the ignition switch, the starter relay or solenoid, and the starter motor. The ignition switch controls the starter solenoid, which activates the starter motor. The starter motor then turns the engine until your car starts.

Belts & Hoses

Exposure to heat, vibration and contamination makes belts and hoses wear out faster than any other components in your car. That’s why regular inspections are so important. Here are the belt and hose types in your car, along with their applications.

Exposure to heat, vibration and contamination makes belts and hoses wear out faster than any other components in your car. That’s why regular inspections are so important. Here are the belt and hose types in your car, along with their applications.

Accessory Drive Belts

While some accessories in your car are electrically powered by the charging system, others use the engine itself as their power source. The power for these accessories is delivered by a system of pulleys and belts. Examples of these accessories are:

Alternator

Water Pump for engine cooling

Power Steering Pump

Air Conditioning Compressor

Radiator Cooling Fan

Many late model cars use a single serpentine belt in place of individual belts to drive these accessories.

HosesThe hoses that convey your car’s fluids are made of two rubber layers with a layer of fabric in between. Typical hoses include:

Radiator and Heater Hoses – These hoses convey coolant to the engine and heater core.

Fuel Hose – As the name implies, this hose transports gasoline from the tank to the engine.

Power Steering Hose – It connects the power steering pump to the steering gear.

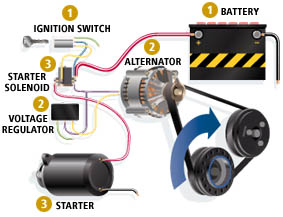

Brakes & Braking Systems

The brake system is actually composed of two kinds of systems—Hydraulics and Friction Materials. Here’s what happens within these systems between the time your foot hits the brake pedal and your car stops.Hydraulics

The brake system is actually composed of two kinds of systems—Hydraulics and Friction Materials. Here’s what happens within these systems between the time your foot hits the brake pedal and your car stops.Hydraulics

Master Cylinder

When pressure is applied to the brake pedal, the master cylinder creates hydraulic pressure which pushes brake fluid to the wheel brakes.

Brake Lines and Hoses

Steel brake lines and high pressure rubber hoses are the avenues through which the pressurized brake fluid travels.

Wheel Cylinders and Calipers

These are the hydraulic cylinders that apply pressure to the friction materials, causing your car to stop.

Friction Materials

Disc Brake Pads and Drum Brake Shoes

These brake linings are composed of high temperature materials that create the friction that stops your car.

Types of Brakes

Disc Brakes

Disc brakes consist of a Disc Brake Rotor, which is attached to the wheel, and a Caliper, which holds the Disc Brake Pads. Hydraulic pressure from the Master Cylinder causes the Caliper Piston to clamp the Disc Brake Rotor between the Disc Brake Pads. This creates friction between the pads and rotor, causing your car to slow down or stop.

Drum Brakes

Drum brakes consist of a Brake Drum attached to the wheel, a Wheel Cylinder, Brake Shoes and Brake Return Springs. Hydraulic pressure from the Master Cylinder causes the Wheel Cylinder to press the Brake Shoes against the Brake Drum. This creates friction between the shoes and drum to slow or stop your car.

Parking Brake

The Parking Brake uses Cables to mechanically apply the brakes (usually the rear brake.) This is used to prevent the car from rolling when not being driven.

Anti-Lock Brakes:

A System Built For Safety

Computer-controlled anti-lock braking systems (ABS) are a recently developed safety feature. When sudden stops are made, the ABS prevents wheel lock-up. The system is comprised of wheel-speed sensors that monitor wheel rotation, computer-controlled hydraulics that pulse the brakes on and off rapidly, and the on-board computer.

Cooling Systems & Maintenance

What Our ASE Certified Technicians Do

What Our ASE Certified Technicians Do

The following components are inspected and condition is recorded and compared to manufacturer’s specs. Recommendations are made per the Motorist Assurance Program Uniform Inspection Guidelines:

Heating and Air Conditioning Systems

Visual Inspection

Interior controls and blowerRadiator coolant level, hoses, pressure cap and thermostatThe A/C compressor belt for condition and tensionLeaks or other damageComponent condition, leaks or damage

Heating and Air Conditioning Tests

Pressure test engine cooling system

A/C system pressures are measured and compared to manufacturer’s specifications

A/C system is leak tested

Both the heater and A/C are performance tested by checking the outlet air temperature at the discharge vents

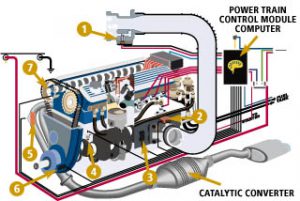

Engine Diagnostics

In order to meet Federal Exhaust Emission and Fuel Economy regulations, today’s vehicles are equipped with highly sophisticated electronic engine control systems. These systems do not require periodic adjustments. The only services required on a scheduled basis are spark plug and filter replacement. Tune-ups, as we knew them, are no longer necessary.

In order to meet Federal Exhaust Emission and Fuel Economy regulations, today’s vehicles are equipped with highly sophisticated electronic engine control systems. These systems do not require periodic adjustments. The only services required on a scheduled basis are spark plug and filter replacement. Tune-ups, as we knew them, are no longer necessary.

Engine Control Computer

The computer receives information from a network of sensors and switches that convert engine operating conditions into electrical signals. Based on the information and instructions stored in the computer program, commands are then sent to three primary systems:

Ignition System

Fuel System

Emission Control System

The sensors that monitor one or more of these systems include:

1. Mass Airflow Sensor

2. Throttle Position Sensor

3. Manifold Absolute Pressure Sensor

4. Coolant Temperature Sensor

5. Exhaust Oxygen Sensor

6. Crankshaft Position Sensor

7. Camshaft Position Sensor

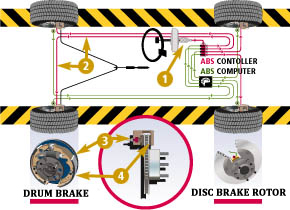

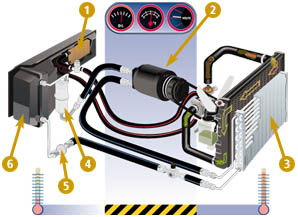

Heating & Air Conditioning

Your car’s engine is the power source for both heating and air conditioning systems.

Your car’s engine is the power source for both heating and air conditioning systems.

The systems also share other components, as the following diagram shows.

Here’s what happens when you flip on the heat or the air conditioner:

Heating System

Heat is a byproduct of the engine’s combustion process. The heat is absorbed by the coolant in your car’s radiator. The coolant is then circulated through the heater core before returning to the radiator. The heating system also includes a series of air ducts, a blower motor and fan, and temperature and duct controls, which selct the desired temperature and direct the flow of warm air.

Air Conditioning System

This system shares air ducts, controls and a blower with the heater, but has its own refrigerant system. The air conditioning system is comprised of the following components:

Compressor

This is a pump that pressurizes and circulates the refrigerant through the system.

Condensor

As the refrigerant flows through the condensor, it gives up heat and converts from gas to liquid.

Receiver/Dryer or Accumulator

This is where clean, dry refrigerant is stored as it circulates through the system.

Orifice Tube or Expansion Valve

This is a metering device that controls the flow of refrigerant through the system.

Evaporator Core

Refrigerant enters the evaporator core as a liquid. Heat from the air converts the liquid refrigerant back into a gas, which cools the air before it enters you car.

Engine Oil

Check the owner’s manual to see if your driving habits are considered to be “severe service.” This type of driving requires more frequent oil changes, warns the Car Care Council. Have the oil changed accordingly, usually every 3-5,000 miles. For less wear and tear on the engine, drivers in cold climes (sub-zero driving temperatures) shoulddrop their oil weight from 10-W30 to 5-W30. Your mom and dad would probably suggest simply moving to someplace warmer.

Check the owner’s manual to see if your driving habits are considered to be “severe service.” This type of driving requires more frequent oil changes, warns the Car Care Council. Have the oil changed accordingly, usually every 3-5,000 miles. For less wear and tear on the engine, drivers in cold climes (sub-zero driving temperatures) shoulddrop their oil weight from 10-W30 to 5-W30. Your mom and dad would probably suggest simply moving to someplace warmer.

Description:

The typical oil filter consists of a high-strength steel housing containing various types of filtering media. An anti-drainback valve prevents oil from running out of the filter when the engine is off. Today’s oil filters have a convenient spin-on design that makes removal and installation easy.

Purpose:

The oil filter sifts out contaminants, allowing the oil to flow through the engine unrestricted. Should the oil filter become restricted or clogged with contaminants, they will flow around the filter. This bypassing is a safety mechanism, but you never want to let oil and filter changes go so long that bypassing takes place.

Maintenance Tips/Suggestions:

For best results, consult your owner’s manual, but consider that your driving probably constitutes a severe maintenance schedule. Usually, this means oil and filter changes every 3,000 miles or 3 months. If you change the filter yourself, dispose of it properly. Take used filters to a facility that accepts them. Used filters can be crushed, removing the used oil and the steel part of the filter can be recycled. The oil from one used, seemingly innocent filter leaking into a landfill can taint 62,000 gallons of ground water.

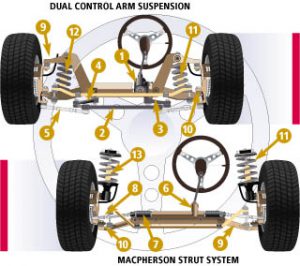

Suspension & Steering

The primary function of your cars suspension and steering systems is to allow the wheels to move independently of the car, while keeping it “suspended” and stable. Any play or uncontrolled motion in these systems results in a deterioration of handling and accelerated tire wear. Vehicle alignment is closely tied to the condition of the suspension and steering systems.

The primary function of your cars suspension and steering systems is to allow the wheels to move independently of the car, while keeping it “suspended” and stable. Any play or uncontrolled motion in these systems results in a deterioration of handling and accelerated tire wear. Vehicle alignment is closely tied to the condition of the suspension and steering systems.

Steering Systems

Worn or loose components affect the ability to control the toe angle, and may result in a loss of directional stability and accelerated tire wear. The main components of a Conventional system are:

1. Steering Gear Box

2. Center Link

3. Pitman Arm

4. Idler Arm

5. Tie Rods The main components of a Rack and Pinion steering system are:

6. Rack and Pinion Assembly

7. Bellows Boots

8. Tie Rods

Suspension System

Worn or loose components affect the suspension systems ability to control motion and alignment angles, resulting in a deterioration of vehicle handling and stability, and accelerated tire wear. The main components of the suspension system are:

9. Control Arms

10. Ball Joints

11. Springs (Coil or Leaf)

12. Shock Absorbers

13. Struts

Tire Repair

One of the leading causes of tire failure and casing rejection during the retread process is a faulty repair. This area is most often overlooked when fleets design tire maintenance programs, but as a recent survey from the monthly magazine Tire Business indicates, 46% of tire failures were caused by improper repair procedures.

One of the leading causes of tire failure and casing rejection during the retread process is a faulty repair. This area is most often overlooked when fleets design tire maintenance programs, but as a recent survey from the monthly magazine Tire Business indicates, 46% of tire failures were caused by improper repair procedures.

Of course this means higher tire costs.When a radial tire has been damaged to the point where the steel cords are exposed to the elements it is important that the area be repaired as soon as possible so that moisture is not allowed to migrate along the belt package causing further damage.

The most effective method of repair for nail holes (1/4″) is the plug and patch repair. The plug stops the migration of moisture and the patch on the inside of the tire supports the plug. For repairs larger than a nail hole (3/8″ and larger) the tire should be removed from service. This method of repair not only reduces the number of tire failures but promotes casing recovery as well.

Tires & Wheels: Tire Rotation

Description:

Description:

Tire rotation refers to the regular practice of switching the position of each tire on the car.

Purpose:

Tire rotation helps to equalize tread wear and is critical to gain the maximum life from your tire investment.

Maintenance Tips/Suggestions:

Refer to your owner’s manual for the recommended rotation interval and pattern; generally a rotation interval of 6,000 miles is recommended. The rotation pattern varies with different makes and models, which shows the tire locations during rotation. Some vehicles have different size tires on the front and back or directional tires. This limits the locations that a tire may take on the vehicle. When in doubt, check the owner’s manual or consult a professional technician for guidance. Tire rotation time also offers a good opportunity to have the tires and wheels balanced. It’s another step you can take to maximize your tire investment.

Transmission Service & Maintenance

Vehicles with automatic transmissions require transmission fluid. It protects the transmission from running too hot, especially during strenuous conditions such as towing or steep hills. If you will be putting more driving stress than normal on your vehicle, it’s important to have your car inspected and serviced to prevent the transmission from overheating. However, completely flushing and replenishing your transmission fluid requires a specially-designed machine.

Vehicles with automatic transmissions require transmission fluid. It protects the transmission from running too hot, especially during strenuous conditions such as towing or steep hills. If you will be putting more driving stress than normal on your vehicle, it’s important to have your car inspected and serviced to prevent the transmission from overheating. However, completely flushing and replenishing your transmission fluid requires a specially-designed machine.

Wheel Alignment

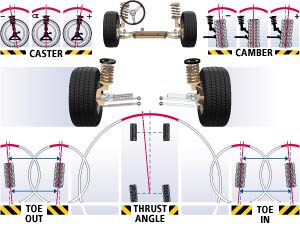

Wheel alignment is the position of the wheels relative to your car. When properly aligned, the wheels point in the right direction. Without proper alignment, the wheels resist your steering commands, as well as each other.

Wheel alignment is the position of the wheels relative to your car. When properly aligned, the wheels point in the right direction. Without proper alignment, the wheels resist your steering commands, as well as each other.

Alignment also affects gas mileage and tire wear. If your tires are pointed in different directions, they fight against each other and can cause tread wear.Computerized alignment equipment is used to measure all alignment angles on today’s cars. These include both adjustable and non-adjustable angles. (Non-adjustable angles require repair or replacement of the suspension component.)

The most common adjustable angles are:

Toe

This refers to the tilted direction of the wheels toward or away from one another when viewed from the top. Toe is the most critical tire wearing angle. Tires that “toe-in” point toward one another. Tires that “toe-out” point away from each other.

Camber

This refers to the tilt of the wheels toward or away from one another when viewed from the front. Wheels that tilt in toward the vehicle have “negative camber.” Wheels that tilt away from the vehicle have “positive camber.”

Caster

This refers to the angle of the steering axis in relation to an imaginary vertical line through the center of the wheel when viewed from the side. “Positive caster” is the term used when the vertical line is tilted back toward the rear. If it’s tilted forward, we call it “negative caster.” The proper caster angle stabilizes your car for better steering.

Thrust Angle

This refers to the relationship of all four wheels to each other, as well as their relationship to an imaginary center line that runs from bumper to bumper. The term “thrust line” refers to the direction in which the rear wheels are pointed. Thrust angle is correctable on cars with adjustable rear suspensions. If your car has a non-adjustable suspension, thrust angle is compensated for by aligning the f

Wheel Balance

Description:Wheel balance refers to the proper distribution of weight around a revolving tire and wheel assembly. Poor wheel balance can have a marked impact on both your car and your safety.

Description:Wheel balance refers to the proper distribution of weight around a revolving tire and wheel assembly. Poor wheel balance can have a marked impact on both your car and your safety.

Purpose:Proper wheel balance ensures that the wheels, while spinning, do not have a heavy spot that can cause vibration and premature wear of tires, struts, shocks and other steering and suspension components. When combined with proper wheel alignment, balanced wheels ensure smooth and enjoyable driving.

Maintenance Tips/Suggestions:The most common signs of unbalanced tires are vibration and noise problems. When driving with an out-of-balance wheel, the wheel literally bounces down the road rather than spinning smoothly. This can affect the speed, handling and mileage of your car. Many of today’s cars have lightweight suspension systems and are therefore, more sensitive to imbalance than older cars. It’s a good idea to have your car’s wheels balanced when rotating the tires, about every 6,000 miles. It’s not uncommon for wheels to lose a wheel weight from time to time; so periodic balancing minimizes the impact of unbalanced wheels on your car.

What To Expect

Respect, quick service and auto repair from experienced technicians. We’ll treat your car or truck like it is our own.

Here at Southside Auto Repair & Tire, we are locally owned and operated. We would like to be your friendly, family oriented repair facility.

Your safety and peace of mind is our priority. We take auto repair & tires very seriously. Paying attention to every detail thereby keeping you and your family safe in whatever you drive.

Come in and meet our staff, have a cup of coffee and let us take your automotive troubles away.